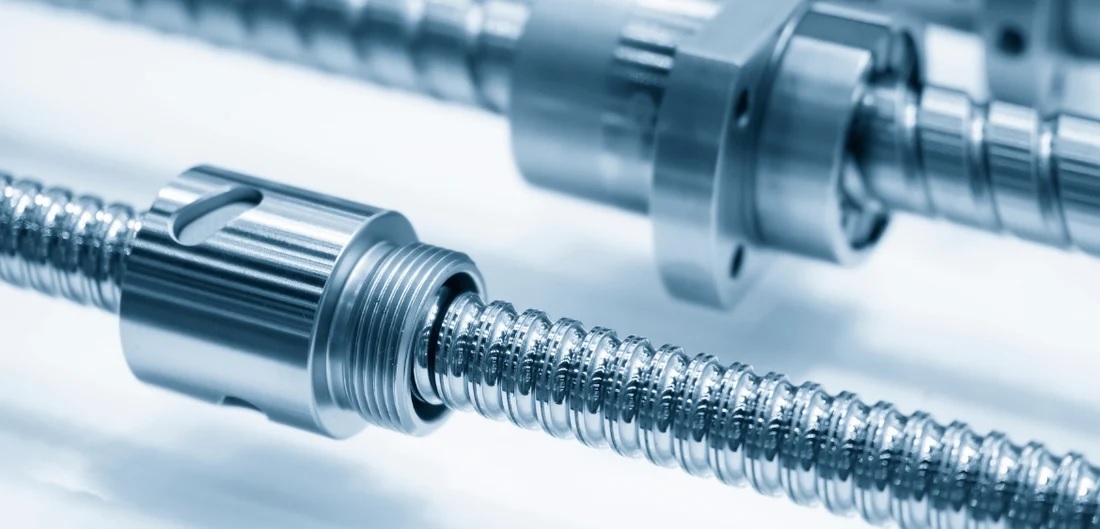

Fasteners play a crucial role in holding projects together and ensuring stability. Choosing the right one can make a significant difference in durability and strength. Understanding the types of fasteners available helps provide a strong assembly. With various choices on the market, it can be challenging to know where to start.

In particular, machine screws are a popular choice for precision applications. They come in various types, each suited for different uses and materials. This guide explains the different kinds and their applications, from head styles to thread options.

Pan Head Fasteners: A Versatile Choice

Pan head fasteners are one of the most widely used. They have a rounded, slightly domed head, providing a flat contact surface. This design is beneficial when working with thin materials, as it won’t dig in. Pan heads also distribute pressure evenly, reducing the risk of damage.

These fasteners offer versatility across various applications. They work well in electrical assemblies, where a flat contact surface is preferred. Pan head fasteners are often a reliable choice for general-purpose tasks.

Flat Head Fasteners: Ideal for a Flush Finish

When fully installed, flathead fasteners create a smooth, flush surface. Their countersunk design allows them to sit level with the material’s surface. They’re often used in cabinetry, furniture, and decorative applications.

Flatheads also help maintain an aesthetic appeal in visible areas. By creating a seamless look, they keep surfaces looking clean and professional. Flatheads are the way to go for applications that require a smooth finish.

Round Head Fasteners: A Classic Choice for Durability

Round head fasteners feature a domed top that extends above the surface. This type is excellent for holding materials together under moderate force. The rounded head provides extra material strength, making it suitable for projects requiring durability. They are commonly used in woodworking, joining pieces without sinking into the material.

Their shape also offers ease of use during installation and removal. Roundheads work well in applications where fastener visibility isn’t an issue. When durability is a crucial consideration, roundhead fasteners are dependable.

Hex Head Fasteners: Strong and Easy to Tighten

Hex head fasteners have a six-sided head, allowing easy tightening with tools. They are often chosen for projects requiring higher torque applications. The hexagonal shape provides a solid grip, making them ideal for heavy-duty tasks. These fasteners are popular in automotive and construction settings.

Hex heads are compatible with wrenches and other standard tools, making them easy to install or remove, even in tight spaces. They are commonly used in assembly lines, providing strength and convenience. If your project needs a robust, accessible fastener, hex heads are an excellent option.

Phillips Head Fasteners: Designed for Precise Alignment

Phillips head fasteners have a cross-shaped drive, which is ideal for precision work. Their design minimizes slippage, making them reliable for detailed projects. The Phillips drive allows for self-centering, reducing the chance of cam-out. This is especially useful in electronics and light manufacturing.

These fasteners are popular in smaller-scale applications where accuracy matters. They are also used in applications with limited access, as they are easy to align. For projects requiring careful alignment, they are a practical choice.

Thread Type and Material Considerations

The type of threading on a fastener affects its strength and application. Coarse threads are best for soft materials, providing a secure grip. Fine threads are more suited for more complex surfaces, offering increased resistance to loosening. Selecting the appropriate threading can improve the longevity of the assembly.

The material also plays a role in the selection process. Stainless steel fasteners resist corrosion and are ideal for outdoor or damp environments. The right combination of thread type and material ensures maximum durability.

Self-Tapping Fasteners: Ideal for Quick, Secure Installation

Self-tapping fasteners are designed to cut their threads into materials. They are instrumental when working with softer wood, plastic, or light metals. These fasteners simplify installation by creating a tight fit without needing a pre-tapped hole. Self-tapping types are often used in projects requiring quick assembly with minimal tools.

This fastener provides a secure hold and minimizes the risk of loosening. It is commonly used for easy installation in automotive, construction, and furniture applications. Self-tapping fasteners save time, reduce the need for additional tools, and create a robust and lasting bond. For projects needing fast, efficient assembly, these are an excellent choice.

Choosing the appropriate machine screws is crucial for reliable project assembly. Each type of fastener has distinct advantages tailored to specific applications and needs. Making an informed decision ensures durability and ease of use, contributing to project success.